Baxter, the affordable, humanoid industrial robot recently unveiled by Rethink Robotics, is so easy to program that I once did it one-handed and drunk. We were at a party at the Massachusetts Institute of Technology (MIT), and he was standing in the corner, looking lonely. No, really–Baxter has expressive eyes projected on a touchscreen where you’d expect it to have a face, virtually guaranteeing that you’ll anthropomorphize it.

Drink in hand, I walked over and, with only the vaguest sense of how to get it to respond to my touch, grabbed it by the wrist. I guided its “hand” over to a box full of small objects. Its caliper-like fingers closed on a widget. Then I moved its hand, which offered almost no resistance at all, to another position on the table. It dropped the object.

After that, it dutifully repeated the procedure I had taught it, again and again, emptying the box. In a display of the sort of capabilities that used to be almost impossible in robotics but are now routine, its machine vision allowed it to cope with the differences in position and shape of each of the widgets. Baxter was untroubled by the poor lighting, loud music or my clumsiness. In less time than it takes to update my calendar, I had, in essence, trained Baxter to pack a box for shipping, or to transfer goods from one conveyor belt to another–two tasks that are common in manufacturing and distribution centers.

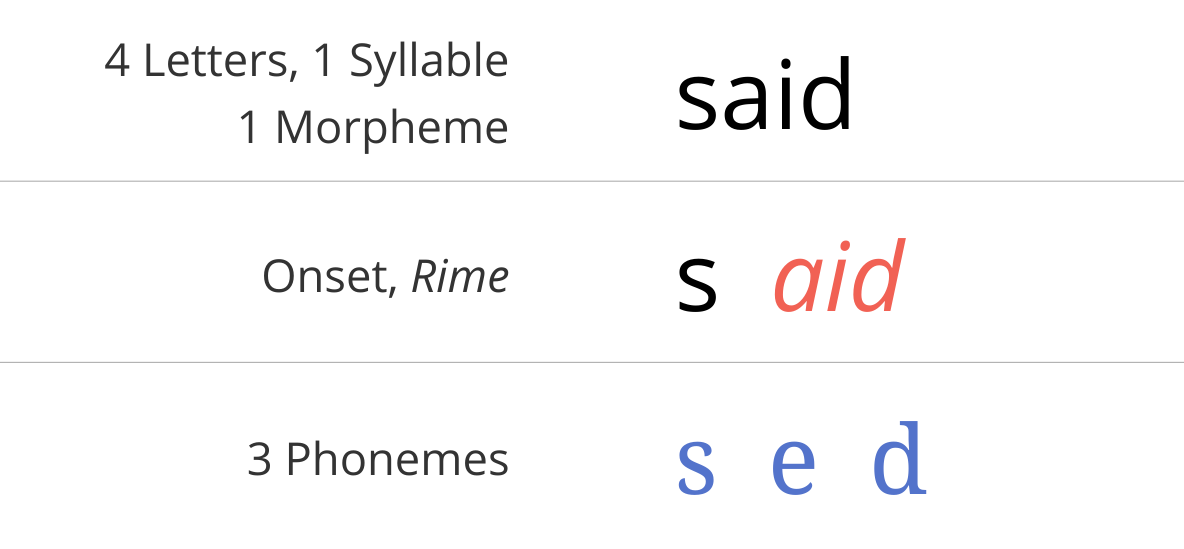

e = get, head

Dive into said